Digitization refers to the use of advanced analytics and data-driven technologies to gather, analyse, and interpret data in the context of a discrete manufacturing industry. This approach helps manufacturers optimise their operations, improve quality, and reduce costs. In other words, this can be termed as Manufacturing Intelligence.

Manufacturing Intelligence typically involves the integration of several data sources, such as real-time production data, quality control data, supply chain data, and customer data. By using analytics tools such as machine learning algorithms, statistical analysis, and predictive modelling, MI can help manufacturers identify patterns and trends in their data that can help improve their operations.

Some of the key benefits of Digitization in a discrete manufacturing industry include:

Improved operational efficiency: Digitization can help manufacturers identify inefficiencies and bottlenecks in their production processes, and make data-driven decisions to optimize production.

Enhanced quality control: Digitization can help manufacturers identify quality issues early in the production process, enabling them to take corrective action before products are shipped to customers.

Reduced costs: By optimizing production processes and improving quality, MI can help manufacturers reduce costs associated with waste, rework, and product recalls.

Increased agility: Digitization can help manufacturers respond more quickly to changes in demand, supply chain disruptions, and other external factors.

Better customer satisfaction: By improving quality and reducing lead times, MI can help manufacturers enhance their customer satisfaction and loyalty.

Overall, Digitization is becoming an increasingly important tool for manufacturers looking to stay competitive in a rapidly changing industry.

Digitization has revolutionised the way discrete manufacturing companies operate and has provided numerous benefits to these organizations. One of the primary benefits of digitization in discrete manufacturing is its ability to increase the availability of industrial assets. Here are some ways that digitization is helping these companies achieve this goal:

Predictive Maintenance: Digitization allows discrete manufacturers to track the performance of their industrial assets in real-time. By analyzing the data generated by these assets, manufacturers can identify potential issues before they occur, enabling them to schedule maintenance and repair work proactively. This approach ensures that equipment is always available and operational when needed.

Remote Monitoring: Many discrete manufacturing companies have assets spread across multiple locations, making it difficult to monitor them manually. With digitization, manufacturers can remotely monitor the performance of their industrial assets, enabling them to detect issues quickly and take appropriate action.

Improved Efficiency: Digitization enables discrete manufacturers to optimize the performance of their assets, ensuring that they are running at maximum efficiency. This optimization reduces downtime and ensures that assets are available when needed.

Data Analytics: Digitization allows discrete manufacturers to collect and analyze large amounts of data generated by their industrial assets. By analyzing this data, manufacturers can identify trends and patterns that can help them optimize their asset performance and availability.

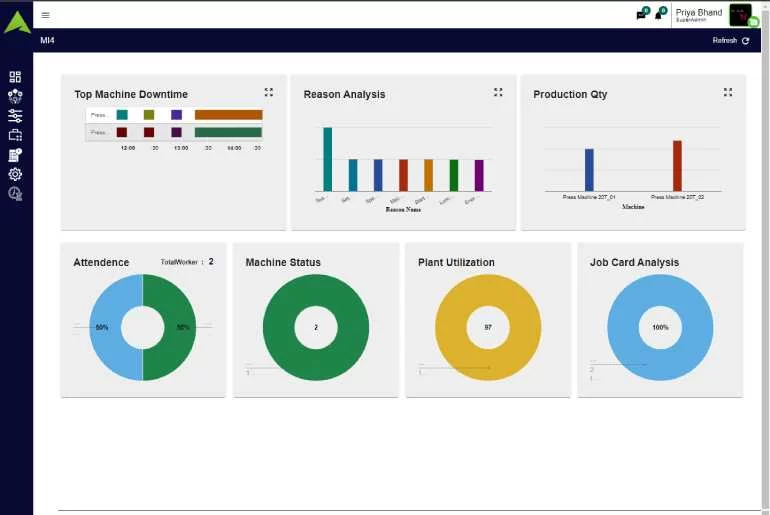

Digitization facilitates Real-time analytics which refers to the process of collecting, analyzing, and using data as it is generated, in order to make timely decisions and take immediate action. In the context of discrete manufacturing, real-time analytics offers several advantages:

Improved visibility: Real-time analytics provides manufacturers with immediate visibility into their production processes, allowing them to quickly identify issues, bottlenecks, and opportunities for improvement.

Faster decision-making: By analyzing data in real-time, manufacturers can make faster and more informed decisions about production processes, maintenance, and resource allocation.

Increased efficiency: Real-time analytics enables manufacturers to identify inefficiencies and optimize production processes on the fly, reducing downtime and improving overall equipment effectiveness (OEE).

Reduced waste and costs: Real-time analytics helps manufacturers identify and address quality issues early in the production process, reducing waste and the costs associated with rework, scrap, and warranty claims.

Enhanced customer satisfaction: Real-time analytics enables manufacturers to respond quickly to customer demands, improve product quality, and deliver products on time.

Predictive maintenance: Real-time analytics can be used to monitor equipment performance and detect potential issues before they result in downtime or breakdowns, enabling manufacturers to schedule maintenance proactively and reduce unplanned downtime.

Improved supply chain management: Real-time analytics can be used to monitor inventory levels, track shipments, and optimize logistics, improving supply chain management and reducing costs.

In conclusion, digitization is helping discrete manufacturing companies to increase the availability of their industrial assets by enabling predictive maintenance, remote monitoring, digital twins, improved efficiency, make faster decisions, increase efficiency, reduce waste and costs, enhance customer satisfaction, enable predictive maintenance, and improve supply chain management.

By leveraging these technologies, manufacturers can ensure that their assets are always available and operational when needed, improving productivity and profitability.

If you are interested in knowing how Asset Intelligence Platform can help you achieve your digitization goals, feel free to talk to us and we will walk you through how our Manufacturing Intelligence solution works and how it can help you achieve your business targets and maximize the asset efficiency considerably.

Inteliiot is a tech-enabled company that unleashes the power of IoT to help you improve your business using various services. By helping our customers create more goods and services while using fewer resources, we at Inteliiot are contributing towards building leaner and more responsible supply chains.